I was privileged to attend and present at the inaugural Geo-Structural Aspects of Pavements, Railways & Airfields (GAP) 2019 Conference a couple weeks ago.

The conference was held in Colorado Springs, Colorado from November 4th thru November 7th.

I learned a lot at this conference – perhaps more than I do at similar conferences on Geosynthetics! To start, I learned the history of how this conference came into being and purpose behind the conference.

The concept originated during the Geosynthetics 2017 Conference as a product of conversations between event (Geosynthetics 2017) organizers and Mike Adams of the Federal Highway Administration (FHWA) seeking a pathway to emphasize the geotechnical aspects of the Transportation Infrastructure within the United States. The focus of such a conference would be to look at the geotechnical decisions impacting things immediately beneath the surface – base, subgrade, aggregate quality, ballast fouling – putting Geotech back to the forefront of the conversation instead of an afterthought. The event sought to bring together Roadways, Railways, and Airfields.

The concept originated during the Geosynthetics 2017 Conference as a product of conversations between event (Geosynthetics 2017) organizers and Mike Adams of the Federal Highway Administration (FHWA) seeking a pathway to emphasize the geotechnical aspects of the Transportation Infrastructure within the United States. The focus of such a conference would be to look at the geotechnical decisions impacting things immediately beneath the surface – base, subgrade, aggregate quality, ballast fouling – putting Geotech back to the forefront of the conversation instead of an afterthought. The event sought to bring together Roadways, Railways, and Airfields.

Incredibly, in a two-year timeframe, GAP 2019 went from conception to reality!

I believe this first conference succeeded in hitting that mark – repeatedly! The program was filled start to finish with a line-up of exciting, articulate industry professionals who shared their knowledge as well as innovative solutions being used to prevent and/or remedy problems.

The first day had two exciting short course offerings and an unforgettable welcome address Geosynthetics Protect our Transportation Assets by Mr. Mark Marienfield who used the term “geo-clueless” to describe the current condition of many college graduates who simply are not being taught how to properly design for long-term sustainability of our transportation infrastructure assets. The second day started with an exciting panel discussion featuring the three conference committee co-chairs (Jeb Tingle, US Army Engineer Research & Development Center; Ted Sussmann, Professor, University of Hartford US DOT Volpe Center; and Mike Adams, US DOT FWHA) and Kevin Vaughan (Vulcan Materials) and Eli Cuelho (TRI Environmental) followed by a slew of educational technical sessions.

Prior to technical sessions, the third day started with Dr. David Pittman, SES, Chief Scientist of USACE and ERDC Director giving a very informative keynote lecture, Cutting through the Complexity: How USACE is Revolutionizing which provided a substantial education on the USACE and concluded with closing remarks by Professor Erol Tutumuluer.

Each day we were given a break, lunch, and a networking reception – we were all well fed! The fourth day consisted of a technical tour to the Transportation Technology Center, Inc. in Pueblo, Colorado where some of the latest and greatest monitoring technologies were shared.

This conference was truly exciting! Not only did I receive a great education, but I met a lot of great and exciting people along the way and hopefully I educated a few people as well during my presentation.

The conference was also very eye-opening! For any of my regular readers, you know that the majority of my background is in containment system construction quality assurance. However, this conference showed there are many parallels and synergies between the two industries in addition to both using geosynthetics. I will briefly mention a few that I came away with in the paragraphs that follow.

By now, my regular audience is aware that I feel there is a critical lack of educated personnel in the containment industry – from regulators, design/certifying engineers, contractors, geosynthetics installers, and Quality Assurance (QA) technicians. One of the key takeaways from the GAP 2019 conference is that same theme – a lack of solid education as well as work force committed to quality. Something has to change here, and conferences like this are one of the many steps needed to pushing us forward into that change.

Similarly, I heard the theme of treating our transportation infrastructure as an asset, and managing it as an asset – the same theme I have been preaching in the containment industry over the last 5 years. Rather than designing transportation systems based on low-cost and aesthetics, design them for the long-term utilizing cost-effective solutions that generate long-term Return on Investment (ROI) through reduced maintenance.

Another parallel is my reference in the geosynthetics industry to completed welds and them being the tip of the iceberg – you can’t visually see anything wrong with them once they are completed but they could be substantially inferior and fail for a variety of reasons once in operation if construction was not performed correctly.

This same principle applies to transportation – the roadway, railway, or runway you see may look great but if it was not constructed properly, it will ultimately fail under operational stresses. What happens if this infrastructure will not hold up to the heavy demands occurring during a national emergency??

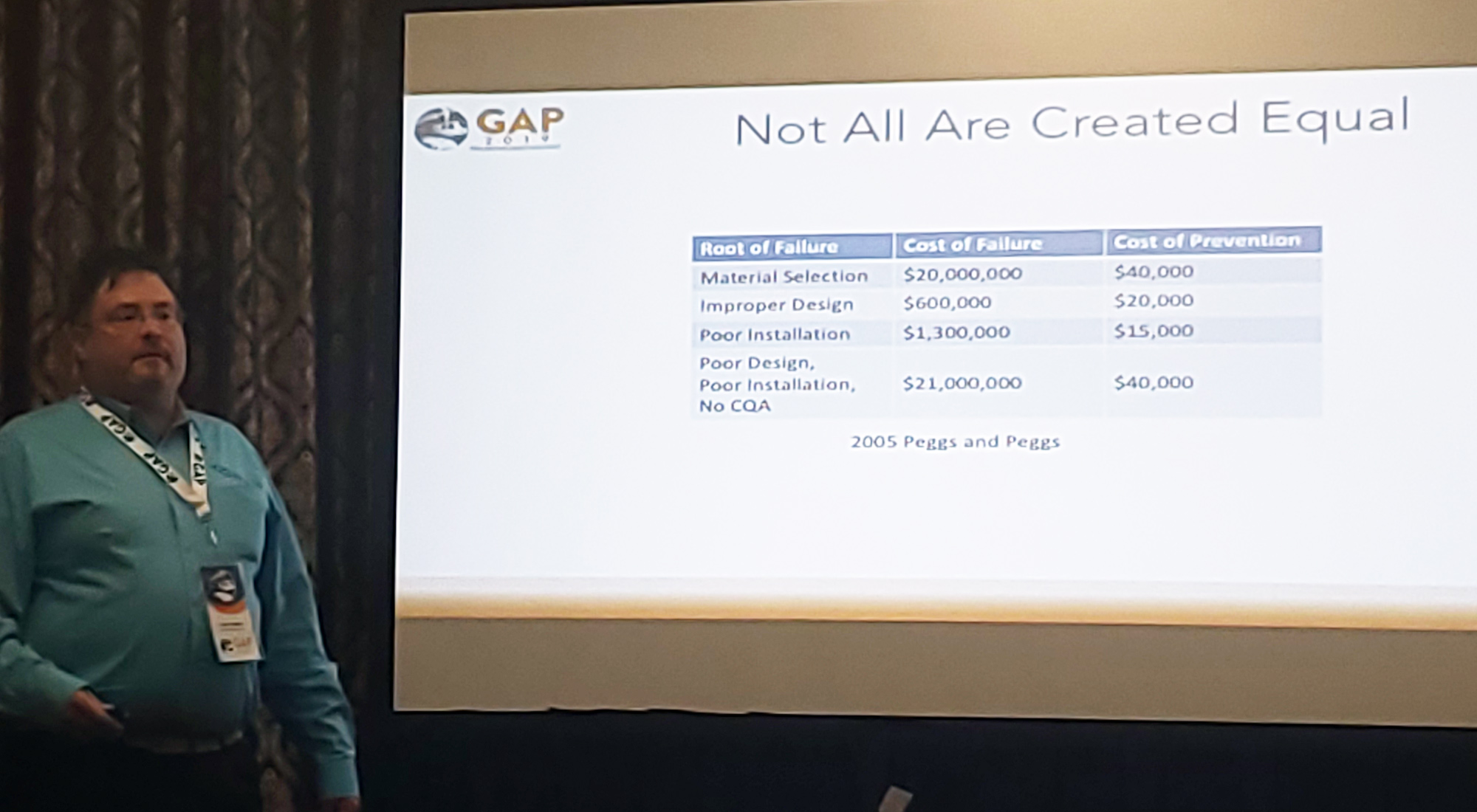

And the final issue I will share at this time – Construction Quality Assurance. This one always hits close to my heart. One of the speakers gave an example of where an error in construction quality assurance directly resulted in a significant failure costing the taxpayer in excess of $100 million in additional costs! We have the same issue in containment system quality assurance, only it sometimes takes 10, 20, or even 30 years to realize there is a problem. We truly need to work on getting things done right the first time, for everyone’s long-term benefit!

My only conference regrets – battling bronchitis (I was on antibiotics which also made me tired), not being able to meet more people, and not taking the tour.

I am eagerly awaiting news of the next GAP conference!