On Tuesday, March 4th a special session is being held at the GEOTECHNICAL Frontiers 2025 conference to discuss welding of geomembranes.

It is scheduled for 1:30-3:00 pm. Panelists for the session include Eric Blond (moderator), Kerry Rowe, George Koerner, Eddie Weiser, Dave McLaury, Todd Harman, Eric Lamontagne, Edward Zimmel.

While I don’t know the exact content the panelists plan on presenting, I am hopeful they deal with (and I will push them during the open discussion time) what I believe is the biggest issue I see in the field – seams that pass peel and shear testing but are compromising the geomembrane quality in the process.

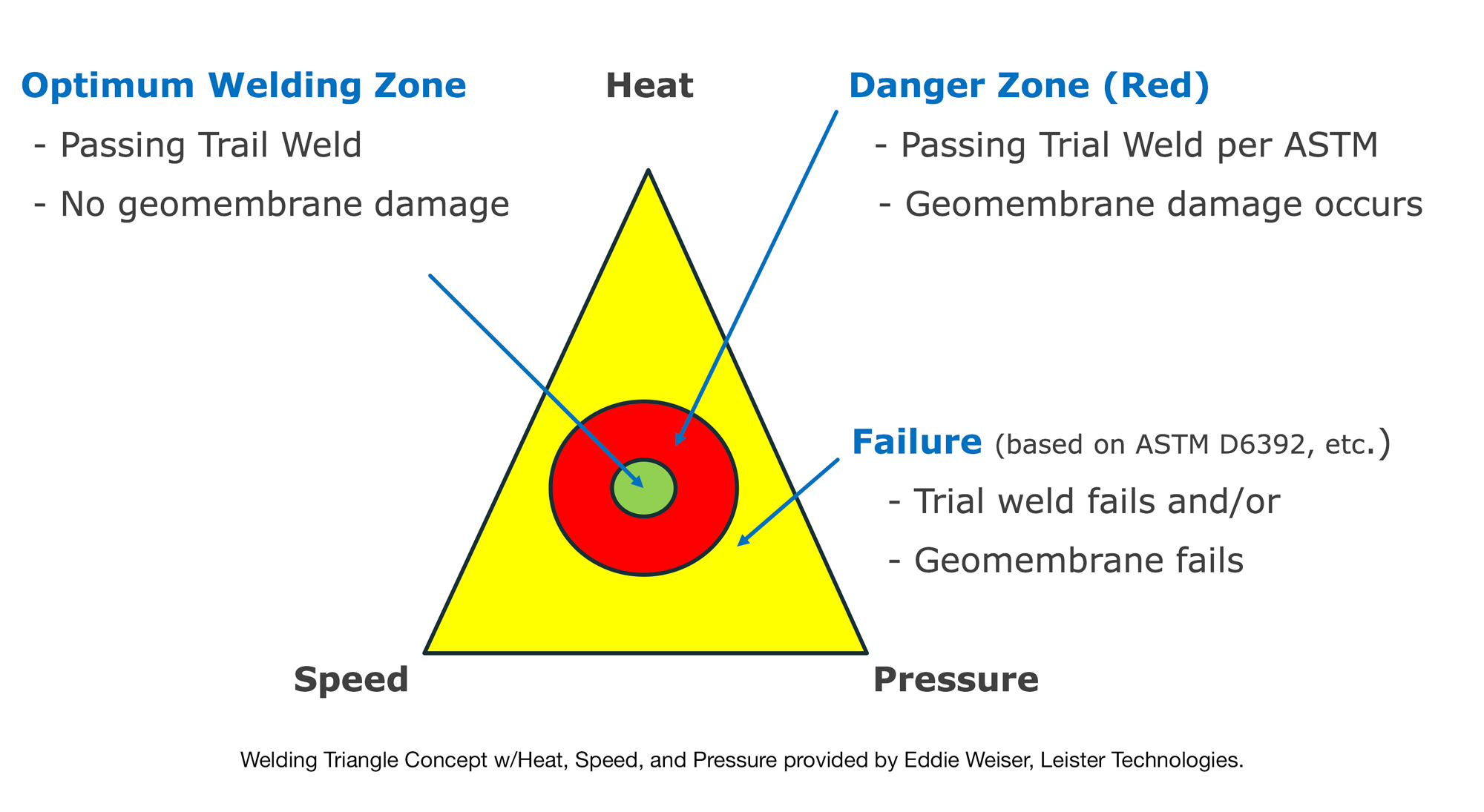

Let’s face it, the geomembrane welding system as we know it is broken. Many installers are overheating the geomembrane seams during welding so they can reduce the failure rate of their trial seams and destructive seam samples. Overheating compromises the long-term integrity of the geomembrane. I illustrated this issue with a target in the triangle above.

Most industry welding experts agree there is an optimal welding zone for all geomembrane materials in which the peel and shear pass while the geomembrane adjacent to the seam is not damaged.

I further believe this zone is also dependent on the manufacturer formulations (i.e. will vary based on manufacture for similar material such as 60-mil smooth HDPE). The danger zone is where the peel and shear tests pass but the geomembrane integrity adjacent to the seam is compromised during the welding, usually through overheating. Then there is the easy to identify failure zone, where the peel and/or shear test fails and/or the geomembrane fails – the failure is obvious, and corrected (or repaired in the case of destructive sample failures).

Many certifying engineers, even when they agree that seam overheating is occurring, say they are powerless to do anything about it because their hands are tied by the construction documents (which only qualify “good seaming procedures” as passing seam destructive tests based on industry standards).

On top of that, we have various industry professionals offering misleading and erroneous guidance suggesting that destructive seam sampling can be reduced or eliminated using either an electrical leak location survey (no correlation to seam integrity) or data recording (the data alone is not going to tell you if the welding temperature is too hot on passing peel and shear tests) all while overheated seams continue to be constructed at an astonishing pace.

I am hoping (and going to push if necessary) the panel deals with this specific issue of overheating to pass trial weld and destructive sample criteria. I am sure there will be some interesting discussion! Hopefully this session will be another step in getting us pointed in the right direction when it comes to quality geomembrane welding!

I’ll keep you posted on what I hear!