First, the answer to Vol. 20 (last week).

Thanks for your responses! Indeed, the operator veered to the right during welding with the dual-track wedge welder, so I am already concerned about the overlap issue. Even more concerning to me are the creases that were welded through, as some of those continue on the top sheet through the weld. Creases should be repaired, and this is an area where now heat has also been introduced to the creased locations at the seam and adjacent to the seam. If I recall correctly, this actually passed an air pressure test, which is surprising given the likelihood of lost overlap on the bottom side. It doesn’t look like the case here, but I’ve seen welding operators add pieces of geomembrane in areas of lost overlap which basically makes the air pressure test passable, and people never give it another thought.

My first recommendation here would be to cut out and remove all the crease material, including the seam and perform a repair. A destructive sample at this exact location, as someone suggested, would be a last resort to use on an uncooperative installer because there probably is not enough overlap remaining on the bottom side to test the coupons. However, if the minimum overlap does not exist for testing, you then usually have the ability to track in both directions to find areas where the overlap does exist. In addition to the removal of the creased material, I would add a destructive sample immediately after that area where the operator got back on track (starting about where the DYSWGS bubble touches the overlap flap). This way, I can make one penetration in the geomembrane that removes the creased material and tests the seam after the veering/welding through creases.

Bonus tip: I learned early on in my career that to figure out which direction a thermal fusion wedge welder ran, remember: “left foot lower”. If you place your left foot on the lower sheet panel and your right foot therefore on the upper sheet panel, you will be facing the direction of machine travel, at least for the machines commonly used here in the United States.

In these blog posts, Do You See What Glen Sees, I will present a photograph or short video related to earthwork or geosynthetics construction and have you identify the significance of what you’re seeing.

It could be things being done correctly or incorrectly. Primarily, these will be things that impact quality.

In addition to my blog, I’ll post this content on X and LinkedIn. You can post your response on one of those two.

I’ll give you my thoughts on each photo or video when I post the next installment.

Do you see what I see? Or did you find something I missed? I’m excited to find out!

Here is the next installment. Take a good look. Do You See What Glen Sees?

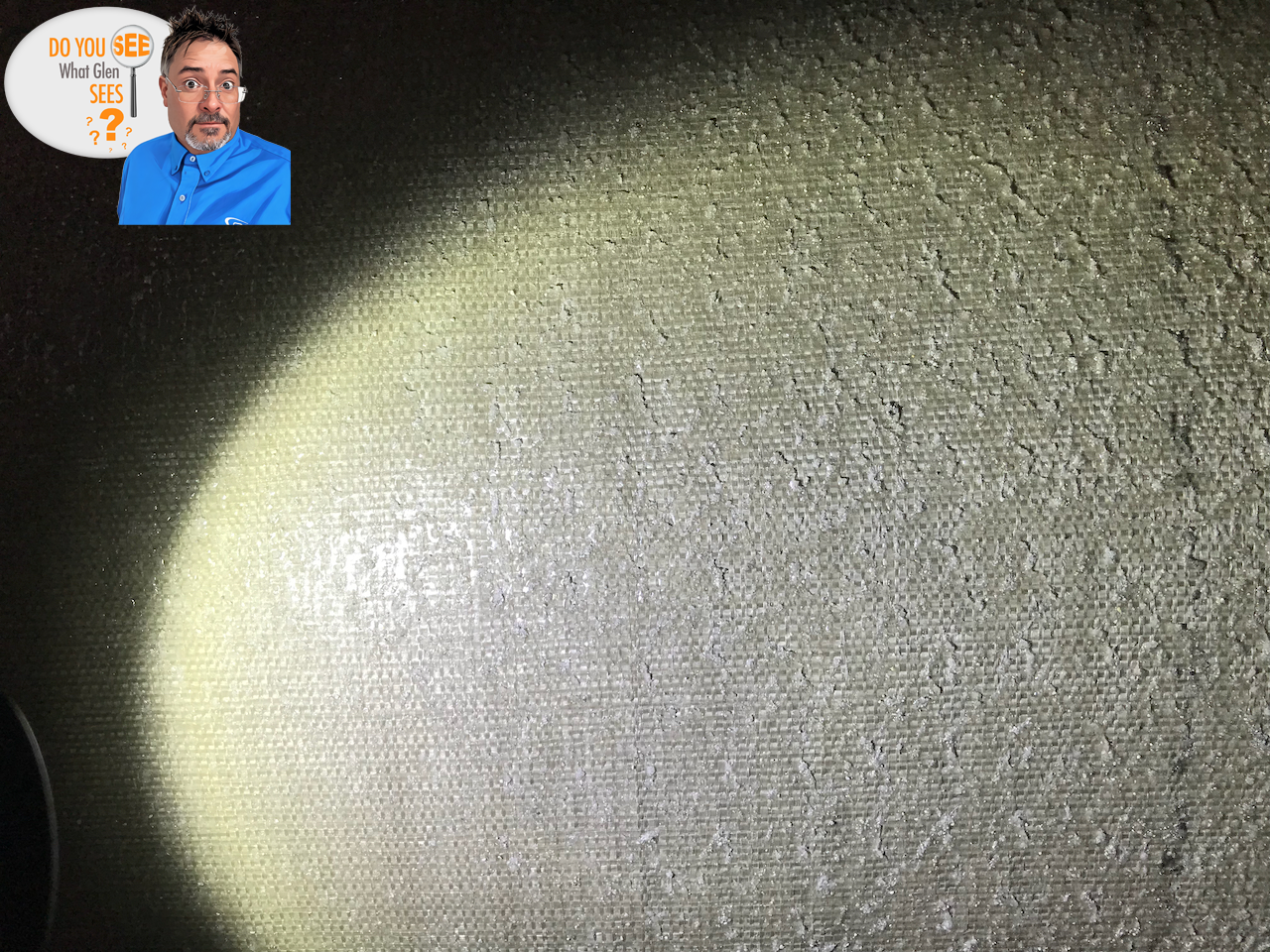

Welcome to volume 21 of Do You See What Glen Sees?! This is something you don’t see (hopefully) every day. I’ve attached a couple photos so you have a bit of reference for the closeup. The close-up is unfortunately not in the same spot or same roll that I am pointing to, as this issue was found on multiple rolls of material.