First, the answer to Vol. 33 (last week).

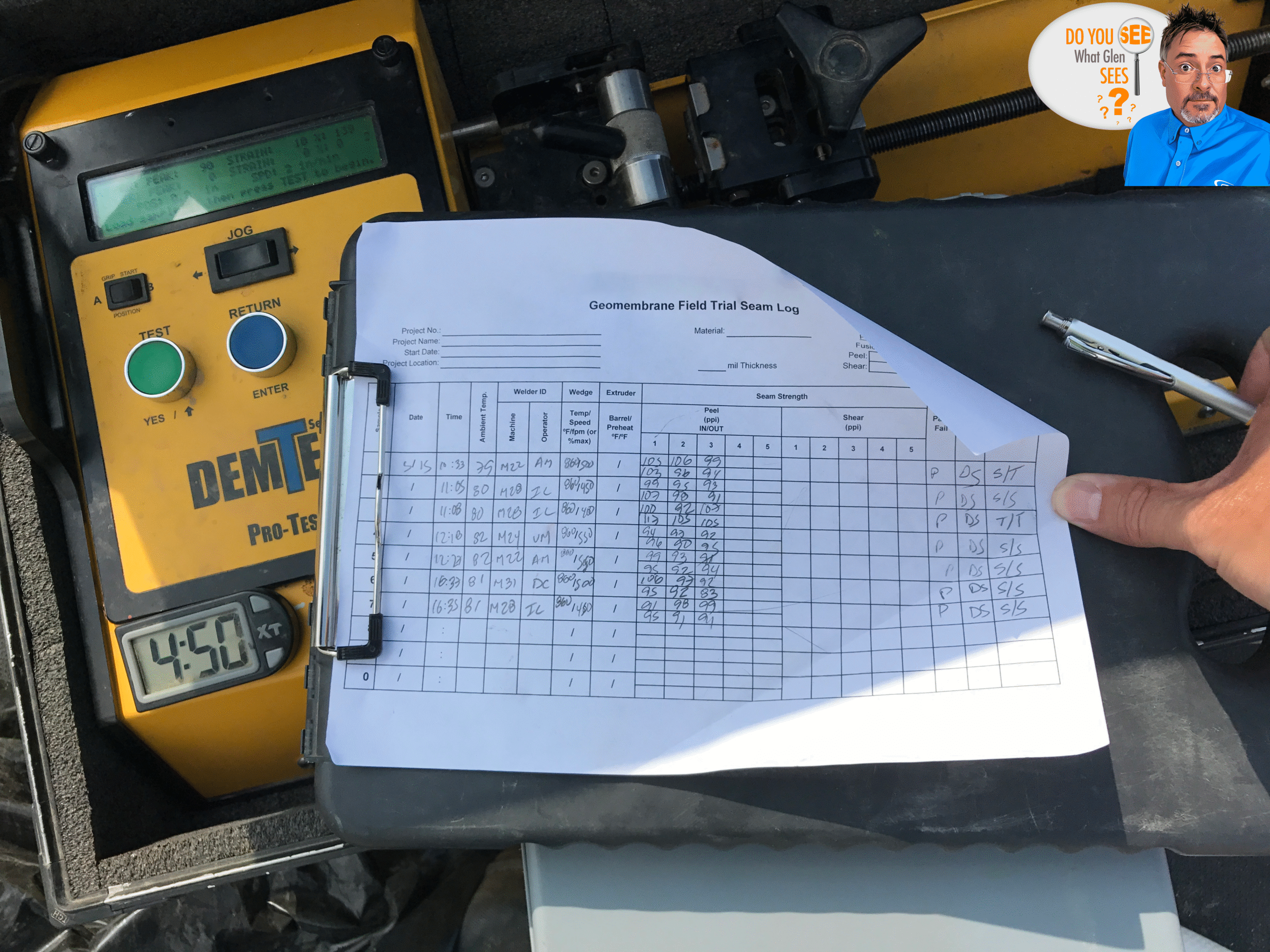

There were many good observations here and I love that questioning mindset!!! Having blanks on a form should always raise questions! I’ll address those blanks first, then get to some of the other items. See the attached image for reference.

The material, thickness, and minimum requirements and number of required tests were missing from the trial weld log, which is critical because the QC has no information handy for comparison. As much as QC’s travel from project to project, this would be a mandatory requirement if I were running the crew! Project information should be there as well (I would have hidden it for project confidentiality) as QC’s sometimes have paperwork for multiple projects traveling with them. Additionally, the project requirement for trial seams was 3 coupons tested for peel and 0 coupons tested for shear. Hence the empty data spaces. The destructive test requirement was also peel only (5-coupons tested in accordance with ASTM D6392).

This is a project where part-time CQA of trial seams was required and even with full-time attempts at observation, the installer would proceed without a CQA person there because it wasn’t required. Note the results! GRI-GM19a requires a peel value of 91 PPI for hot wedge seams. Two test coupons (labeled #1 and #2 in the yellow boxes) both failed to meet this requirement yet were marked passing by the QC! Another coupon (labeled #3 in the yellow boxes) is recorded as 91 PPI but the last tensiometer strength left on the display panel shows 90 PPI! Unfortunately, some installation personnel seem to take great liberties when it comes to rounding whole numbers upward!!!

If you look at #4, you can see the time the photo was taken – about 15-minutes after welding, less than that for the testing.

Guess what? The electronic version submitted by the installer to the engineer after project completion had all these low values as passing values!!! And, destructs on seams welded by these three operator/machine combinations failed miserably in the lab resulting in hundreds of feet of unnecessary cap – all performed using extrusion welding instead of the CQA recommended fusion welding!

Stay vigilant!

In these blog posts, Do You See What Glen Sees, I will present a photograph or short video related to earthwork or geosynthetics construction and have you identify the significance of what you’re seeing.

It could be things being done correctly or incorrectly. Primarily, these will be things that impact quality.

In addition to my blog, I’ll post this content on X and LinkedIn. You can post your response on one of those two.

I’ll give you my thoughts on each photo or video when I post the next installment.

Do you see what I see? Or did you find something I missed? I’m excited to find out!

Here is the next installment. Take a good look. Do You See What Glen Sees?

Volume 34 of ‘Do You See What Glen Sees?‘ certainly took me down memory lane – not because of the content of the photograph, but because the release date is 9/11, the 24th anniversary of that tragic act of terrorism. I still remember where I was when the planes hit the towers – the first impact having me question how that could happen and whether it was intentional; the second impact leaving no doubt and filling my mind with uncertainty. Please take a moment to remember those who lost their lives and the sacrifice many others made thereafter.

There are several things I see in this photo that warrant being commented on.

Do you see what I see? Let’s find out – tell me what you see.