First, the answer to Vol. 32 (last week).

Congratulations to Mark, who nailed it – the installer brought in a full second crew overnight.

So, how do you handle it?

There was no notice given – they just show up, an additional 11- or 13-man crew. Everyone (owner/engineer/CQA team) made staffing plans for the weekend based on the installers Friday forecast of weekend activities pertaining to 1-crew. Only one CQA technician was planned for the weekend, and only one CQA technician (myself) was available when I discovered the extra crew at 6:30 am Sunday morning. Scheduled weekend activities included finishing air pressure testing Sunday with possibly some detailing and repairs to follow – a short day.

Once the second crew showed up, the plan was to track failed destructive samples, fusion seaming of caps, extrusion seaming and repairs (all requiring multiple interface trial welds), air pressure testing, vacuum testing and potentially geotextile placement across approximately 5-acres of a 10-acre project. One CQA technician to monitor the activities of up to 26 installation personnel??? I don’t think so! A call to the certifying engineer gave the following response: “handle it the best you can”.

How as a certifying engineer can you have this response??? Why don’t you tell the installer “no” when a crew shows up unannounced?? I’ve seen this happen time and time again over my career and I simply don’t get it. One CQA technician cannot do the project justice covering a crew this size with that many activities going on, let alone two crews this size. I feel like I’m better than average at being able to spot things, but that’s way too many activities for one CQA technician to try to monitor.

Where does the responsibility for this lie? The installer? I can see where they would want to keep their crews busy and if they feel their crew is doing a great job, what is the problem? The owner? Ultimately, it is on the owner if anything happens – they will be sued by the regulatory agency. The engineer? I believe so – you are certifying that you believe everything was properly constructed in accordance with the CQA Plan, etc. How can this be when these activities cannot be properly monitored?? And even furthermore, when the engineer is made aware there are quality issues observed with this second crew and allows them to keep going. CQA Personnel? Potentially – I think stop work authority should be given to CQA both for quality and safety issues. This was not the case here and CQA was powerless to do anything about it. As a result, jobs can suffer. Maybe the crew is good and does a good job – but that’s not always the case and in some instances the opposite is true – they do more harm than good. Without adequate CQA coverage, you may never know which you got.

The bottom line is that everyone needs to work together as a team for staffing. If an additional crew is going to show up, advance notice should be provided within an agreed upon timeframe (e.g. 48-hour’s notice) by the installer.

In these blog posts, Do You See What Glen Sees, I will present a photograph or short video related to earthwork or geosynthetics construction and have you identify the significance of what you’re seeing.

It could be things being done correctly or incorrectly. Primarily, these will be things that impact quality.

In addition to my blog, I’ll post this content on X and LinkedIn. You can post your response on one of those two.

I’ll give you my thoughts on each photo or video when I post the next installment.

Do you see what I see? Or did you find something I missed? I’m excited to find out!

Here is the next installment. Take a good look. Do You See What Glen Sees?

Welcome to the 33rd volume of ‘Do You See What Glen Sees?’!

A bit of context for this photograph:

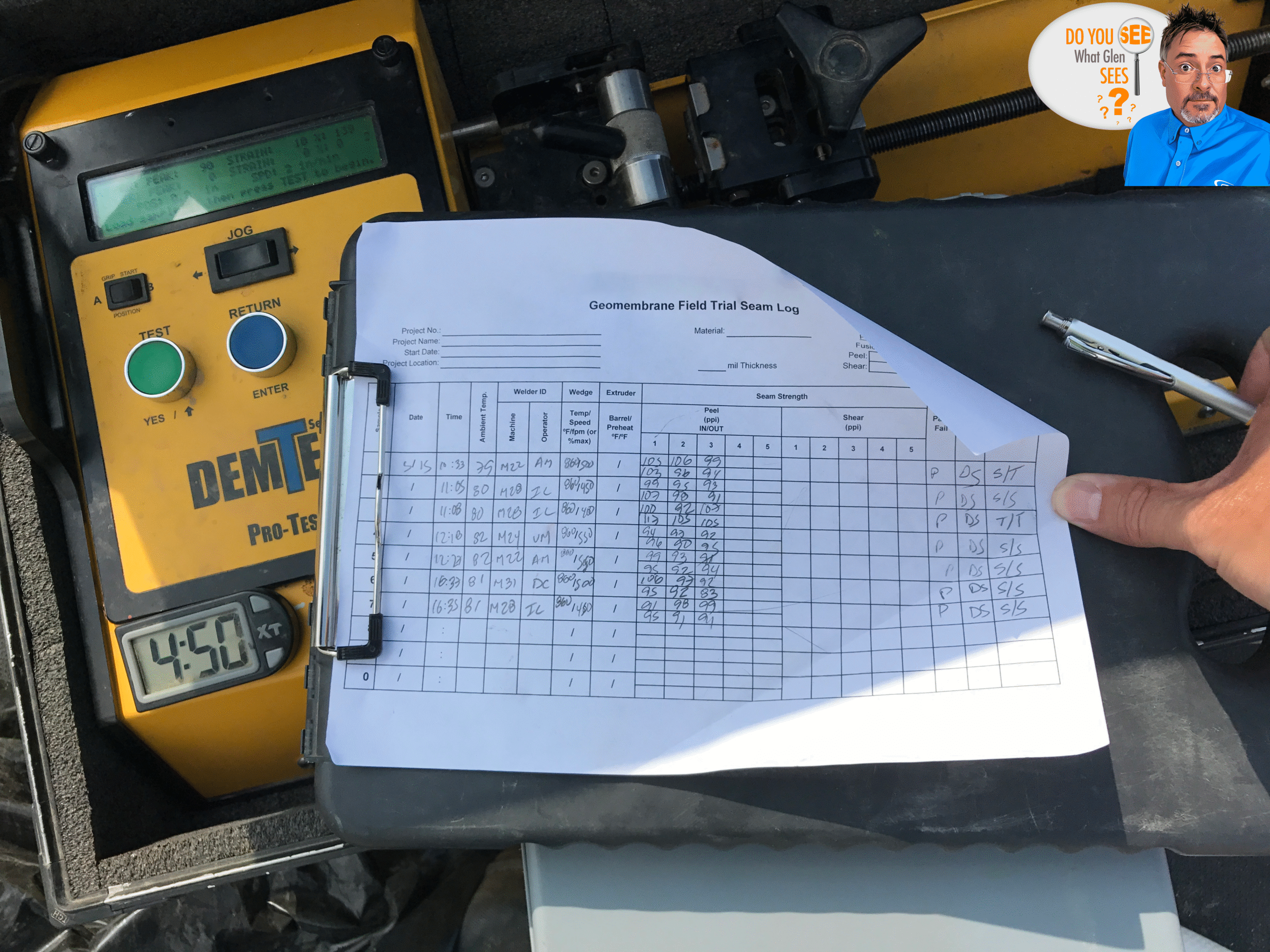

- You are looking at the installers trial weld log that was laying on the tensiometer

- 60-mil textured geomembrane w/smooth welding edges being installed

- Trial welds need to meet the requirements of GRI-GM19a

What do you see?