Thank you so much for your participation in the recent air pressure testing of dual track fusion seams quiz.

Like our last quiz, the response was overwhelming! And, to those of you who e-mailed me your score and commented on how much fun you had – thank you for sharing! I really am enjoying the ongoing dialogue.

To add to the fun, we anonymously collected all quiz results to date. Since I received a lot of feedback after releasing the last set of industry scores, I thought I would do so again. If any of you are as curious as I was, here are the results.

Air Pressure Testing Quiz Results

For each of the possible scores, 0-5 correct, the graph shows the percentage of individuals who had that many correct answers.

Breakdown Of Quiz Takers

Individual Question Results and Observations

The mean score was 2.25 (or 45%).

To me, it is interesting that questions 2 and 5 were the only ones with more correct answers than incorrect answers. Because people e-mailing me privately composed the entire spectrum of our industry, I believe it is important to take a look at each question and the answers given to these questions. In taking this approach, I will provide some observations following each question, with further discussion at the end.

QUESTION 1

Per the ASTM, a calibration certificate is required for the air pressure test gauges every 12 months. In the United States, new pressure test gauges come with a factory calibration certificate.

CORRECT ANSWER: FALSE

More than half of us got this one wrong. I believe this should be an eye-opener for our industry. There is a huge misconception that calibration certificates actually come with the gauges. The only way to obtain a factory calibration certificate is to pay extra for it.

Got Question 1 Correct

QUESTION 2

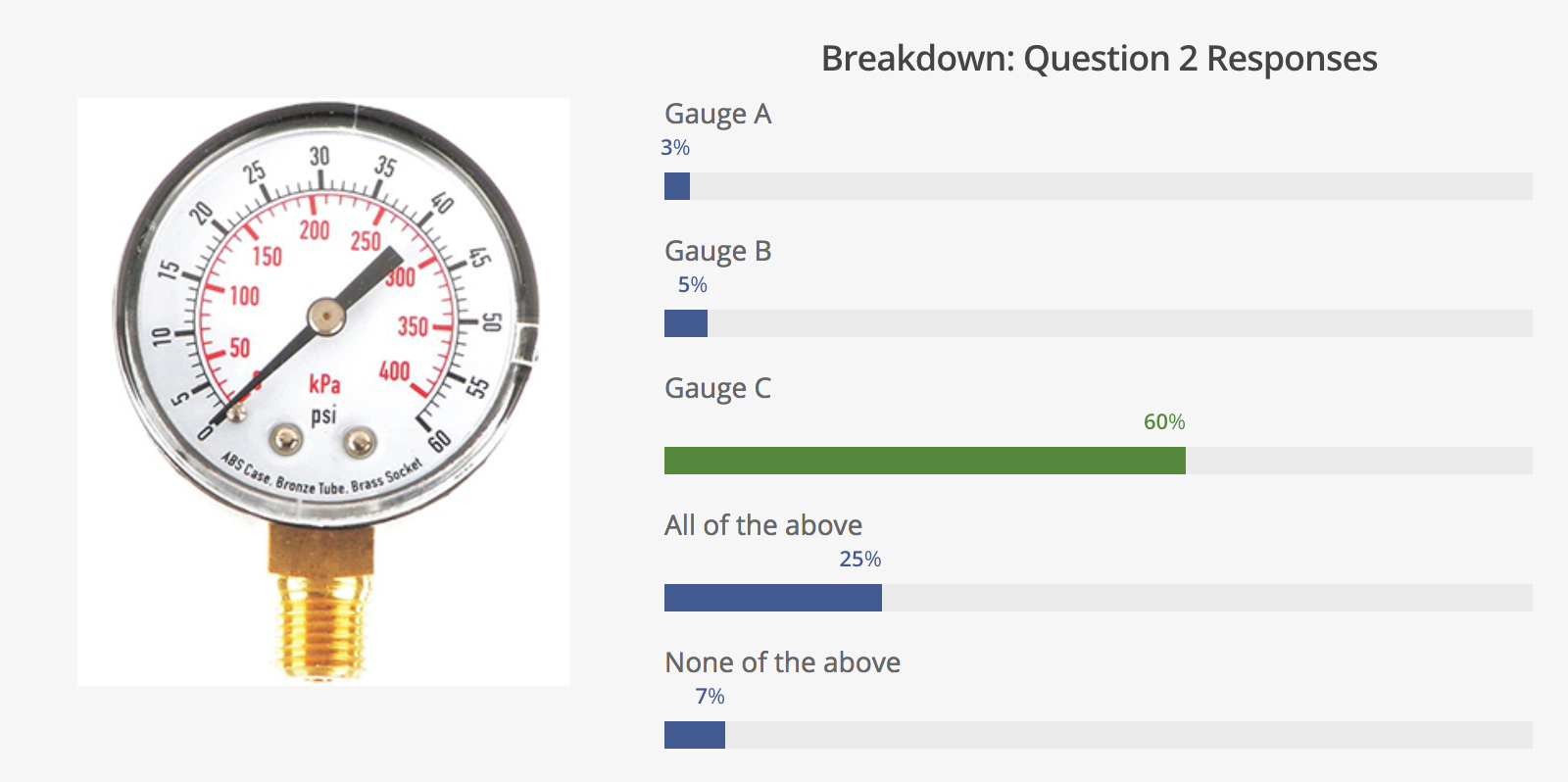

Based on the photographs below, which gauge (or gauges) meet the ASTM requirement for use in testing 60 mil HDPE geomembrane (assumes calibration certificate is not an issue)?

CORRECT ANSWER: C

It is noteworthy that 60% of you did identify the correct gauge – good work!

However, 40% of us got this wrong. Moreover, 25% thought all three gauges we acceptable.

While I suspect the division between those correctly identifying the gauge and those not may come from those having field experience versus those not having field experience, there is no way given this data set to draw a valid conclusion. The only conclusion that can be drawn is that there may be more training required in this area.

Breakdown: Question 2 Responses

QUESTION 3

Pressure stabilization is required prior to starting the official test. The minimum required stabilization period (in minutes) is:

CORRECT ANSWER: Not defined within the ASTM

Again, congratulations to the 40% who answered this question correctly!

Of those answering the question incorrectly, it is interesting to note that highest percentage of incorrect answers were given for 2 minutes (27%). This perhaps correlates to my theory that this 2-minute time is often used in specifications; therefore, the incorrect association is made that the stabilization time comes from the ASTM itself.

Breakdown: Question 3 Responses

QUESTION 4

The minimum required starting test pressure (in psi) is:

CORRECT ANSWER: Not defined within the ASTM

Congratulations to the 22% of you who correctly answered this question!

The one thing that stands out to me: of the 78% who answered incorrectly, the predominant answer was 30 PSI (52% of total answers, or 66.7% of incorrect answers).

Breakdown: Question 4 Responses

QUESTION 5

When the pressure loss is greater than the maximum allowed drop at the conclusion of the test duration, the test technician should first:

CORRECT ANSWER: Check the seals of the seam at both ends and around test apparatus for leaks

Congratulations to the 59% of you correctly answering this question!

One take-away from this question is that only 1% of people taking the quiz chose either of the first two answers. To me, this means that people taking the quiz were really putting thought into figuring out the correct answer and not merely random guessing as those two answers make the least logistical sense. Even with answer 3 thrown in, only 15% of those with incorrect answers chose answers 1-3, meaning the choice really came down to knowing the content of the ASTM.

Breakdown: Question 4 Responses

Additional Discussions

The greatest take away I have from this quiz is that more education is needed in regards to the ASTM D5820-95. While many people know a few details of ASTM D5820-95, very few of us know all of the details. I lump myself in there as well, because without the knowledge I compiled in putting this quiz together, I would have scored 2 or 3 out of 5 without some lucky guesses.

A couple other items I would like to follow up on are the stabilization time and the 30-psi minimum starting pressure.

Does anyone know where the common 2-minute stabilization time comes or where the 30-psi minimum starting pressure come from that are so commonly referenced in specifications?

I know the GRI GM6 document is still active and sometimes referenced for materials other than HDPE and LLDPE; is there something regarding these two items in this GM6 document? I do not have a copy of this document and it does not appear readily available on the internet.

As some follow-up research to several individuals who sent me comments on the quiz, I noticed that the 30-psi minimum starting pressure is referenced in the September 1993 EPA/600/R-93/182 Technical Guidance Document: Quality Assurance and Quality Control for Waste Containment Facilities. This document also contains a the text: “Details of the [pressurized dual seam] test can be found in GRI Test Method GM6.”

I would love to hear your answers to the above questions as well as your feedback regarding the quiz or any of the other information I have put out regarding this testing process.